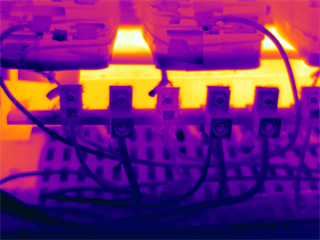

Every DoyleElectric technician maintains valid NFPA 70E and First Aid/CPR training, and many have specialized advanced training to quickly diagnose and repair power quality issues, circuit breakers, and motors.

Our dispatch team strives to offer prompt response to your reactive service and repair needs. Some clients choose to utilize maintenance contracts to establish regularly scheduled visits, while others opt to have Doyle Electric’s expertise on-site at all times. And, we provide 24/7 response for any emergency situations.

Fill out the contact form below to speak with a professional, or contact us at 225-367-1750 or at service@doyleelectricinc.com.