Our team works to review schedules and identify assemblies that can be assembled off-site eliminating waste, accelerating scheduling and improving jobsite safety using a pre-fabrication process.

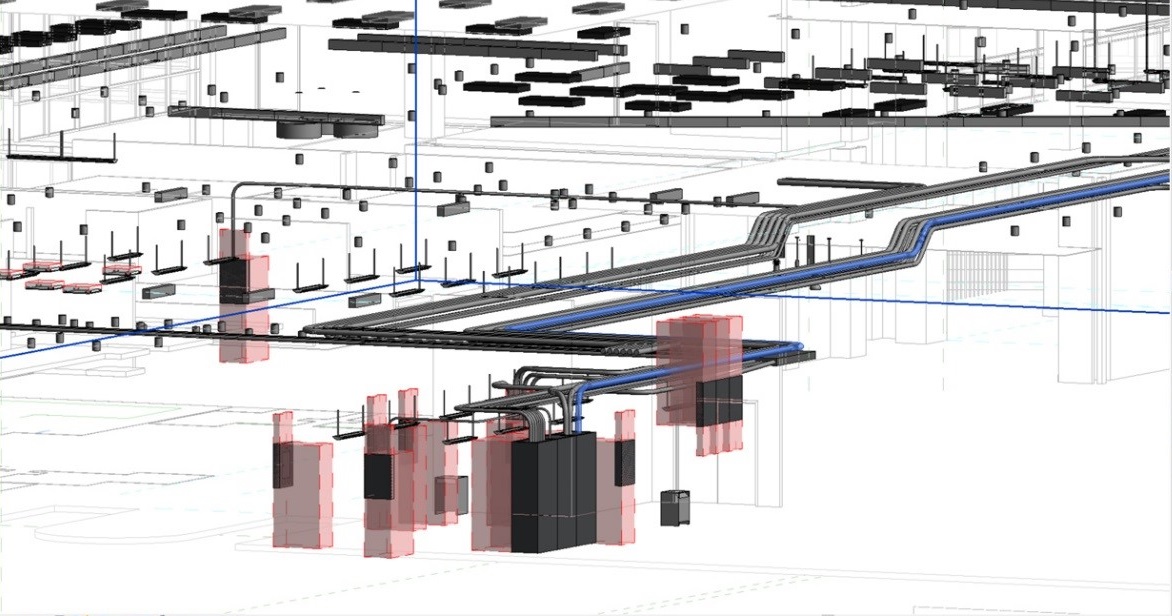

Building Information Modeling (BIM) is implemented, providing dimensioned layouts of equipment rooms, identifying conflicts and resolutions and laying out major routes for electrical feeders and branch circuits.

Our Construction Management Systems include monthly cost-to-complete projections ,weekly short-interval schedules, and internal Milestone Meetings, ensuring that we know where our jobs are and where they are headed at all times.